Turbomachinery

Current trends towards renewable energy and other alternative sources and the energy pricing policy do not favor investment in large energy units. Local energy sources with heat recovery , and cogeneration for the production of are increasingly being used. From these compressors, micro turbines, single-stage expanders to conventional multi-stage turbines, all are used in these machines.

TechSim Engineering provides complete engineering from designing and optimizing the cycle to designing the jet parts - impellers, nozzles, diffusers and output cabinets, ensuring their strength and dynamic control:

| Offered Solution | Analysis Type | Software |

|---|---|---|

| Analysis and optimization of working cycles for cogeneration of energy | 1D 3D CFD |

Simcenter Amesim Simcenter STAR-CCM+ |

| Reduction of COx and NOx emissions | 3D CFD | Simcenter STAR-CCM+ |

| Optimization of stationary and rotating parts of turbines and compressors for increased efficiency | 3D CFD | Simcenter STAR-CCM+ HEEDS |

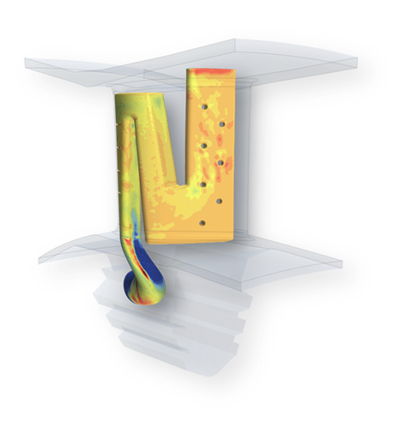

![[turbinarstvi9.jpg]](https://www.techsim.cz/content/images/turbinarstvi9.jpg)

Calculation of the gas turbine blades - Design of single stage combustion turbine arrangement

Thermal Calculations

When designing larger power turbines, the construction currently requires specifications for increasing temperature parameters of the working medium as well as for rapid start-ups and shutdowns, especially when used as an industrial power source or in solar power plants. Compliance with these requirements needs accurate temperature field prediction due to possible large temperature gradients. TechSim Engineering offers the following types of calculations in this area:

| Offered Solution | Analysis Type | Software |

|---|---|---|

| Combined role of CFD / FEA heat conduction on real geometry, including multilayer materials including temperature-dependent material properties | 3D CFD 3D FEA |

Simcenter STAR-CCM+ Simcenter 3D |

| Determination of heat transfer coefficients for heavily stressed flow parts | 3D CFD | Simcenter STAR-CCM+ |

| Flow in labyrinth seals and inter-body spaces | 3D CFD | Simcenter STAR-CCM+ |

| Deformation and relief of turbine bodies considering the contact of bodies, prestressed screws, plasticity and creep | 3D FEA | Simcenter 3D |

| Simulation of forced blade vibration - flutter | 3D CFD, 3D FEA | Simcenter STAR-CCM+ |

Optimization of blade cooling channel

Condensers and heat exchangers

In addition to steam, cogeneration and tricogeneration units can also work with CO2 and various types of refrigerants. Computational simulations allow for predicting the behavior of these substances even during phase change - evaporation or condensation.

| Offered Solution | Analysis Type | Software |

|---|---|---|

| Design and optimization of flow condenser and evaporator parts including multiphase flow | 1D | Simcenter Amesim |

| Conjugated heat transfer (CHT) task with condensate formation and runoff | 1D | Simcenter Amesim |

| Strength calculations of heat exchanger and condenser constructions according to relevant standards | 3D FEA | Simcenter 3D |

Steam turbine condenser

Strength problems

Due to the high revolutions and dimensions of the impellers, especially in the last stages of the turbines, it is necessary to provide a wide range of strength and dynamic calculations, including the preload from the screws, the thermal load considering the plasticity of the material, creep models and life predictions. TechSim Engineering has specialists in the following types of analysis:

| Offered Solution | Analysis Type | Software |

|---|---|---|

| Static linear and nonlinear analyzes considering temperature fields, prestressed connections and contacts Statické lineární a nelineární analýzy s uvažováním teplotních polí, předepjatých spojů a kontaktů | 3D FEA | Simcenter 3D |

| Dynamic problems - modal analysis, rotor dynamics Harmonic and transient analyzes with cyclic symmetry |

3D FEA | Simcenter 3D |

| Reduction of DOFs of blade disc models - fast harmonic and transient analyzes (considering the damping effect of contacts) | 3D FEA | Simcenter 3D |

| Low and High Cycle Fatigue | 3D FEA | Simcenter 3D |

| Creep - use of different material models for primary, secondary and tertiary area, determination of Larson-Miller parameter | 3D FEA | Simcenter 3D |

| Propagation of fatigue cracks, determination of critical crack size, determination of residual life | 3D FEA | Simcenter 3D |

Acoustics

Recently, we have been acknowledging customer requirements for dealing with noise levels in power equipment, both in terms of vibration and aeroacoustic noise itself. Techsim Engineering offers both computational simulation and acoustic camera or intensity probe measurements.

| Offered Solution | Analysis Type | Software |

|---|---|---|

| Simulation and prediction of vibrating and aeroacoustic noise of rotating machines | 3D FEA 3D CFD |

Simcenter 3D Simcenter STAR-CCM+ |

| Vibroacoustic analysis of gearboxes, compressor housings and turbines | 3D FEA | Simcenter 3D |

| Simulation of electromagnetic noise of electric motors, generators and transformers | 3D FEA | Simcenter 3D Simcenter Magnet |

| Measurement of noise and vibration | Simcenter Testing Solutions | Simcenter Scadas Simcenter TestLab |

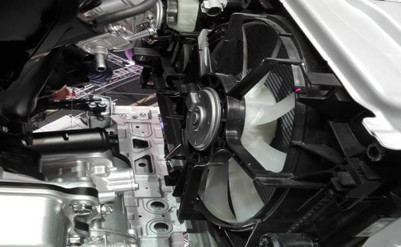

Measurement of fan noise