News

3D Printing: More Than Just Prototypes. A True Revolution in Industrial Manufacturing

When people hear "3D printing," many envision small plastic models and rapid prototyping. However, this vision falls far short of reflecting the reality and true potential that additive manufacturing (AM) brings to the industrial world. Today, it's no longer about mere experimentation; additive manufacturing is becoming a key technology for serial production, fundamentally changing how we design products, organize manufacturing, and conduct business.

Breaking Old Barriers

Traditional manufacturing methods come with a host of limitations. Complex shapes mean expensive molds and tooling, weight reduction often comes at the cost of strength, and lead times are extended by complex supply chains. Additive manufacturing shatters these barriers and opens the door to innovations that were previously unimaginable.

It allows us to:

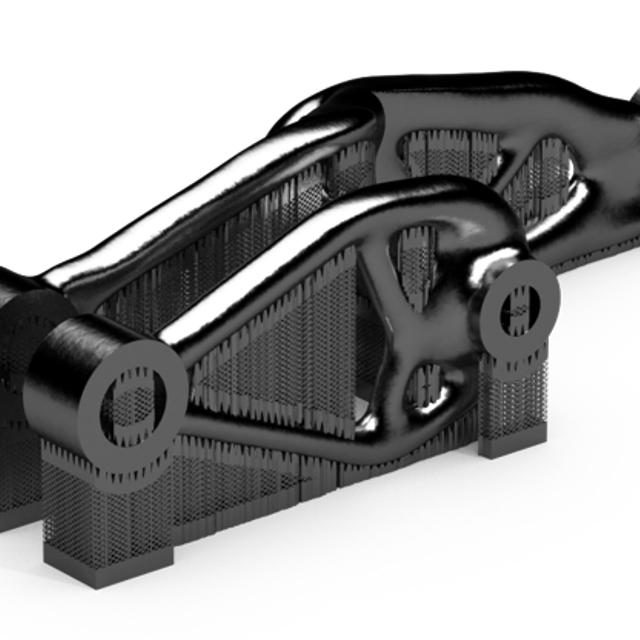

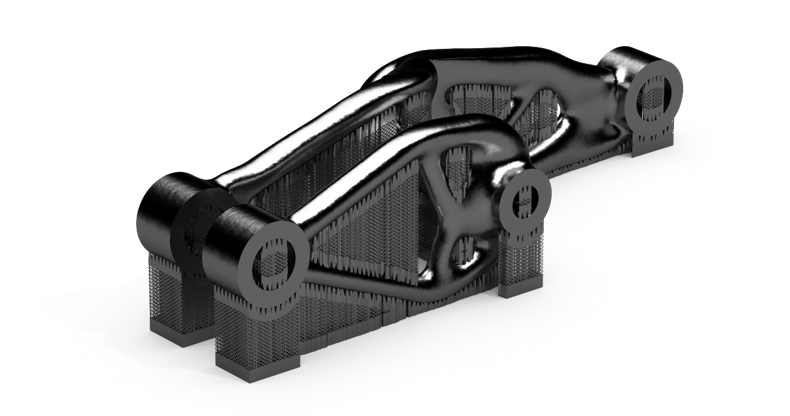

- Reimagine Products: We can create parts with optimized internal structures (e.g., lattice structures) that are both lighter and stronger. It enables personalization and custom manufacturing without increasing costs.

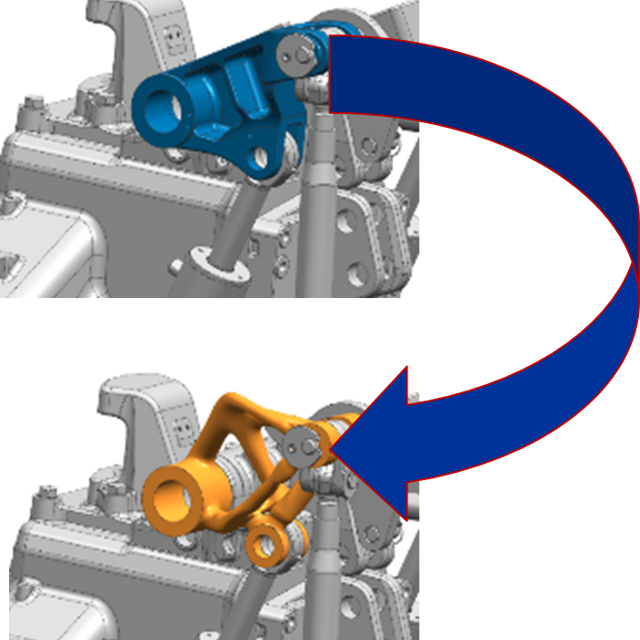

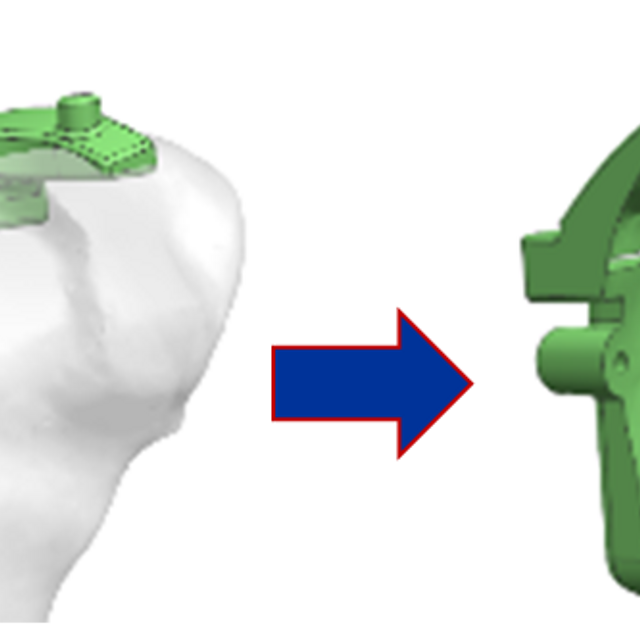

- Reinvent Manufacturing: Shape complexity is no longer an obstacle. Parts that were previously assembled from dozens of components can now be printed as a single piece, simplifying assembly and reducing the risk of errors.

- Rethink Business: Inventory can shift from physical warehouses to a digital format. Parts are printed on demand, exactly where they are needed, dramatically shortening supply chains and increasing flexibility.

The Challenge: The Path to Industrialization

However, the transition from prototyping to serial production is not simple. The main obstacle is process fragmentation. Design, simulation, print preparation, and manufacturing itself often take place in separate software environments. This leads to constant data conversions, loss of information, and an inconsistent, difficult-to-control workflow. To achieve true industrialization, this chain must be connected.

The Solution: The Power of an Integrated System

The vision for the future, now being realized by leaders like Siemens, lies in a single, end-to-end software system that covers the entire product lifecycle. This approach ensures that data flows seamlessly through all stages without the need for conversions and the associated risks.

This integrated process is built on three pillars:

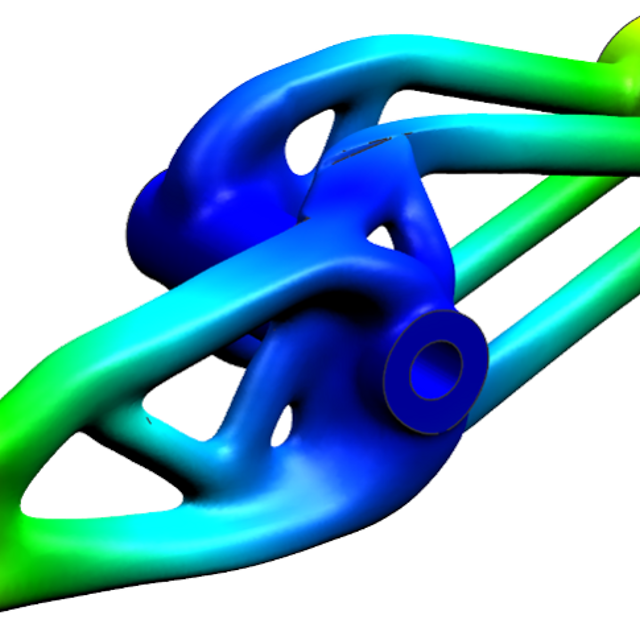

- Design for Additive Manufacturing (DfAM): This isn't just about designing a model "somehow" for printing. Modern tools like topology optimization and generative design allow the software to design the ideal part shape based on specified conditions (loads, material, spatial constraints). Furthermore, technologies like Convergent Modeling™ enable seamless work with different types of geometry (faceted and precise), dramatically accelerating the design process.

- Simulate for Additive Manufacturing: Predictability is key. It's necessary to simulate not only the final properties of the product but also the printing process itself. Advanced simulations can predict distortions caused by thermal stress, residual stress in the material, or the risk of collision with the recoater blade. This allows the model to be adjusted beforehand to ensure the final product meets the exact requirements.

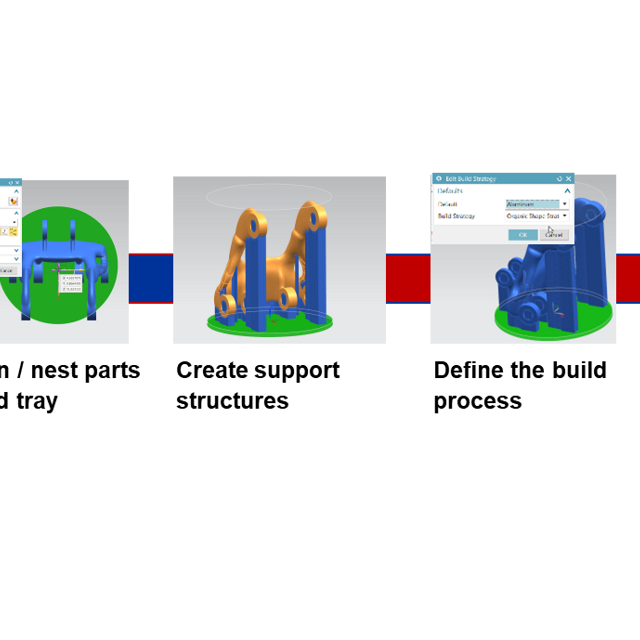

- Print Preparation and Management: An integrated system must support a wide range of printing technologies—from metal Powder Bed Fusion and HP's Multi Jet Fusion for plastics to multi-axis printing (Multi-Axis DED). Preparation includes optimally arranging parts in the build chamber, generating support structures, and defining print parameters. Integrating subsequent operations, such as CNC machining to achieve final surface precision, is also a crucial component.

The Digital Thread: From Design to Finished Part

Data management is the foundation of everything. The entire process must be connected by a digital thread, ensuring that everyone is working with current and correct data. From the initial design through simulations, manufacturing preparation, and production data—everything is connected and traceable. This concept of a digital twin for both the product and the production process is the absolute cornerstone of reliable and efficient industrial additive manufacturing.

Additive manufacturing has matured. It is no longer just a technology for enthusiasts but a robust industrial process that, thanks to integrated software platforms, allows companies to produce faster, cheaper, and better than ever before.