News

Simcenter Amesim: Advanced Fluid System Simulation for Faster and More Accurate Development

20/10/2025

Why Simulation is Essential

Modern industry faces growing system complexity, pressure to shorten development cycles, and demands for higher performance and reliability. Traditional approaches based on physical prototypes are costly and time-consuming. The solution lies in model-based engineering and tools that allow system behavior to be simulated before manufacturing.

Simcenter Amesim: An Integrated System Simulation Platform

Simcenter Amesim is a scalable 1D/0D multi-physics simulation platform that enables:

- Virtual assessment and optimization of performance from concept to validation

- Multi-physics libraries for hydraulics, pneumatics, thermodynamics, electrics, and controls

- Control strategy verification (MiL, SiL, HiL)

- Integration with CAD/CAE tools and support for FMI and Modelica® standards

Key Capabilities

- Steady-state and transient analysis

- Isothermal and thermal simulation

- CAD model import (Parasolid, STEP, native formats via extensions)

- Advanced fluid property models (aeration, cavitation)

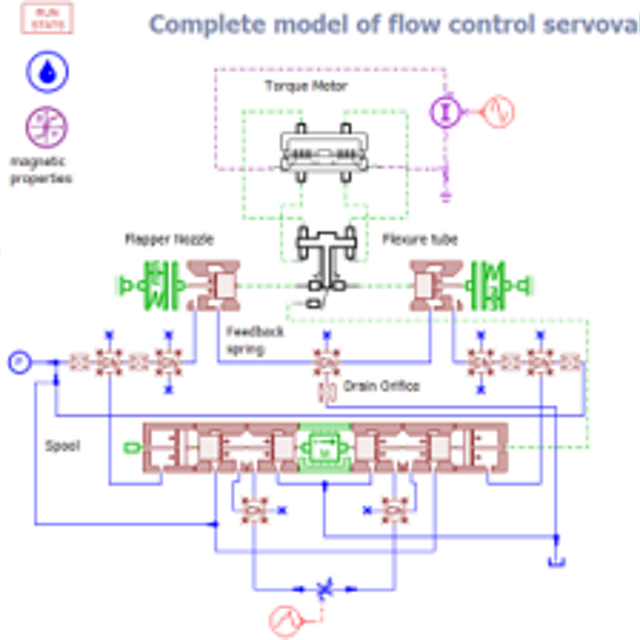

- Valve Builder tool for directional valve generation

- Optimization methods (DOE, Monte Carlo) and parallel processing

Libraries and Databases

- Hydraulics: pumps (axial, gear, gerotor), valves, accumulators, filters; models with hysteresis, water hammer, power and energy calculations

- Pneumatics: models for gas injection, high-pressure storage, real gas behavior

- Thermo-hydraulics: heat transfer, cavitation, aeration, multiple thermodynamic assumptions

- Fluids and Materials Database: viscosity as a function of pressure/temperature, effective bulk modulus

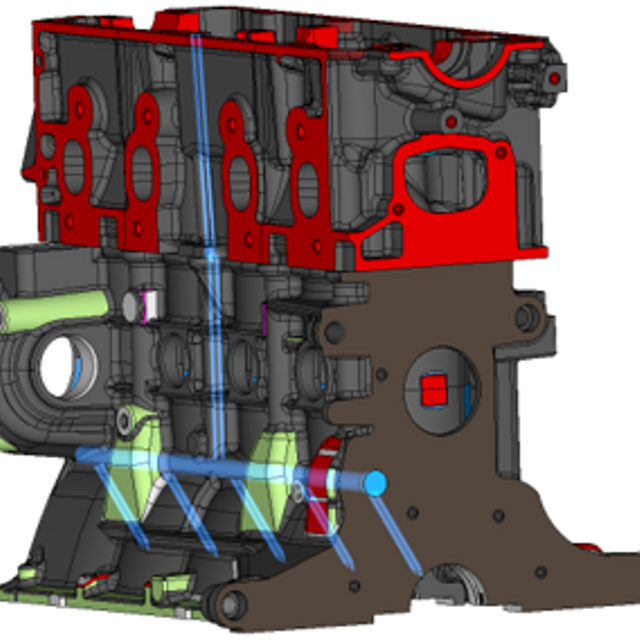

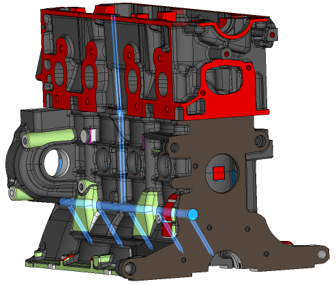

- CAD Import Support: automatic model generation from geometry, integration with 3D mechanics and CFD

Integration and Openness

- Coupling with CFD (STAR-CCM+), FEA (Nastran), and MBS for detailed analysis

- Interfaces with Matlab/Simulink

- Model exchange between suppliers and OEMs with IP protection (model encryption)

- Cloud deployment on Rescale platform (SaaS, HPC)

What’s New

- Enhanced CAD import – automated geometry extraction

- Graph Digitizer with color detection – easy data extraction from catalog curves

- Solver optimization for large systems

- Support for Executable Digital Twin (xDT) for virtual sensors, training, and operational optimization

Typical Applications

- Axial piston pumps – pressure regulation analysis, piston inertia effects

- Gear pumps – NVH optimization (noise, vibration)

- PLC validation – Software-in-the-Loop simulation with PLCSIM Advanced

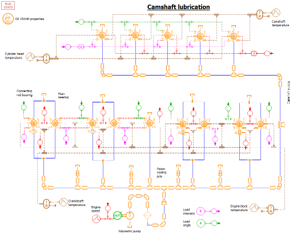

- Engine lubrication systems – oil flow simulation, power loss analysis, pump calibration

- Directional control valves – static and dynamic behavior, stability analysis

Benefits for Development

- Reduced number of prototypes and physical test campaigns

- Shorter development time thanks to fast simulations, even for large systems

- Higher quality and reliability through detailed modeling and validation

- Improved collaboration between teams and suppliers

Real-World Examples

- Kawasaki Precision Machinery: optimized valve plate design → reduced noise and pulsations

- Liebherr: fewer prototypes and improved cross-site collaboration

- Airbus Helicopters: hydraulic system optimization cycle shortened by 3×, prototype costs reduced by 4×

.png)